Introduction

This study is focused on the analysis of the valvetrain stress when changing from the LEA1 to L15A7 cam and rocker assembly coupled with upgraded valvetrain components in the case of a CVT equipped CR-Z.

OEM, Supertech, Brian Crower (PAC Racing) and CAT Cams valvetrain components are considered in this analysis. The objective of this analysis is to find the most reliable combination of components which increases the performance (air flow in this case) of the cylinder head. The valvetrain mass, acceleration and spring rates all play a crucial role in determining the reliability and performance of the valvetrain as a whole.

General LEA1 V.S. L15A7

The LEA1 and L15A7 engines share many of the same components, including connecting rods, pistons, valve springs, head and block castings, with the exception of the 2011 (first year) CR-Z which used a slightly different head casting part number. The crankshafts, however are slightly different for the two engines throughout all model years, the L15A7 having 0.4mm longer stroke (89.4mm vs 89mm) than the LEA1. Interestingly, the Honda parts websites list the LEA1 crank as an alternate to the L15A7.

The press release specifications from Honda can be found here and here for the LEA1 and L15A7 equipped cars respectively.

| LEA1 (CVT) | |

| Peak Power | 82.8kW @ 6000RPM |

| Peak Torque | 142.4Nm @ 4800RPM |

| Redline (CVT) | 6300RPM |

| VTEC Window | 2300-3600RPM |

| L15A7 | |

| Peak Power | 87.3kW @ 6600RPM |

| Peak Torque | 145.0Nm @ 4800RPM |

| Redline | 6800 |

| VTEC Window | 3500-5300RPM |

Valvetrain Overview

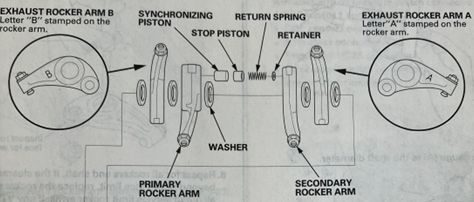

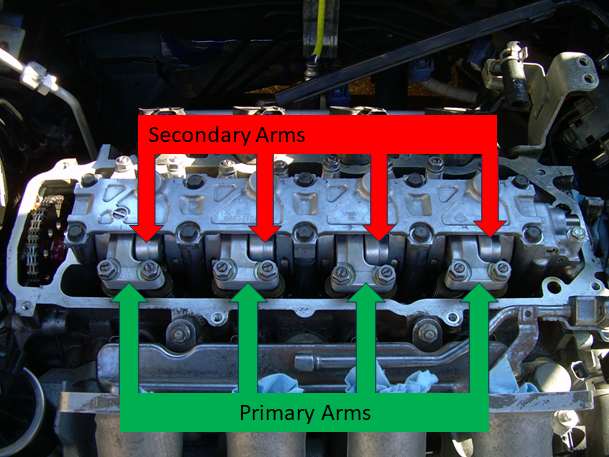

The LEA1 engine utilizes an i-VTEC system which operates as a 3-valve head (one intake, two exhaust) until VTEC is engaged, and the second intake valve is allowed to fully open.

The L15A7 engine utilizes an i-VTEC system with always uses all 4 valves but changes to a higher lift/duration intake cam lobe when VTEC is engaged.

Neither system adjust Exhaust Valve lift or duration.

The table below describes the operation of the two valvetrains:

| LEA1 | L15A7 |

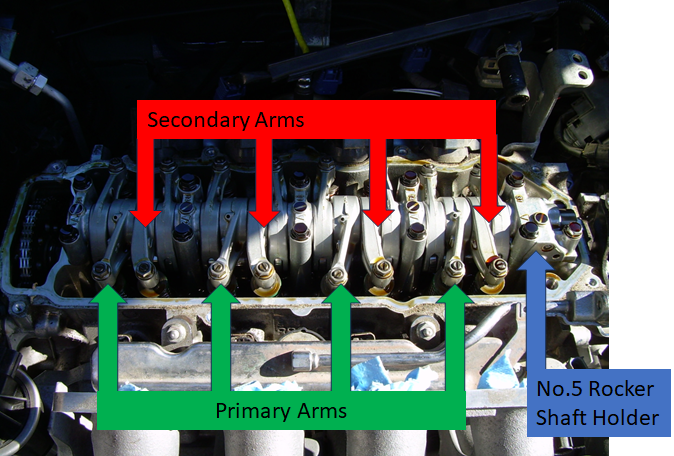

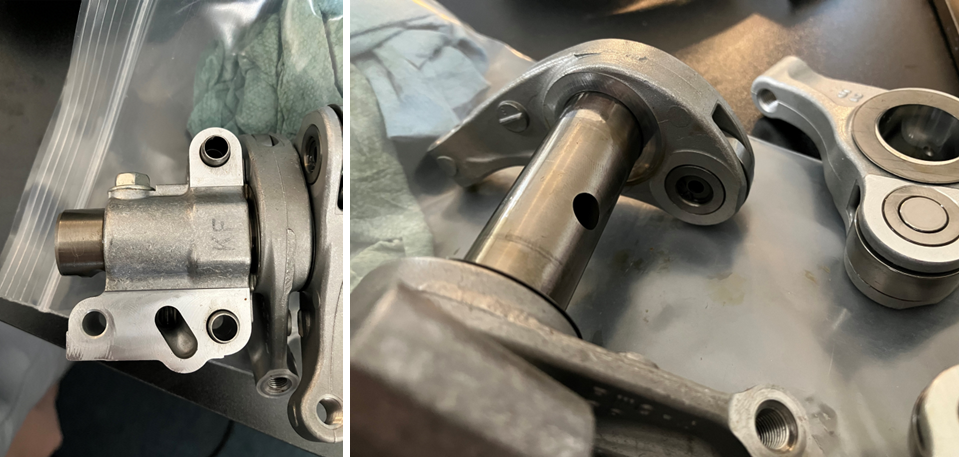

| The rocker arms rotate about a hollow steel shaft that is supplied with oil | The rocker arms rotate about a hollow steel shaft that is supplied with oil |

| When the VTEC solenoid opens, the rocker shaft oil pressure rises, fed from the No.5 rocker shaft holder (on the drivers’ side in the US) and it is forced into oil galleries in the rocker arms | When the VTEC solenoid opens, the rocker shaft oil pressure rises, fed from the No.5 rocker shaft holder (on the drivers’ side in the US) and it is forced into oil galleries in the rocker arms |

| These oil galleries lead to the synchronization piston cylinders which force the synchronization pistons into the adjacent secondary rocker arms | These oil galleries lead to the synchronization piston cylinders in the secondary rocker arms which force the synchronization pistons into the adjacent primary rocker arms |

| The secondary rocker arm receives the synch piston into a cylinder containing a spring-loaded stop piston to prevent the synch piston from ejecting from its cylinder | The primary rocker arm receives the synch piston into a cylinder containing a spring-loaded stop piston to prevent the synch piston from ejecting from its cylinder |

| Once VTEC is no longer active, oil pressure in the rocker shaft drops and the spring-loaded stop piston returns the synch piston to its original rocker arm | Once VTEC is no longer active, oil pressure in the rocker shaft drops and the spring-loaded stop piston returns the synch piston to its original rocker arm |

LEA1

L15A7

Aftermarket Components

Supertech HEVI-1050-8 Inconel Exhaust Valves

Supertech HVIN-1050-8 Black Nitride Intake Valves

Supertech SPRK-H2416 Valve Springs

Supertech RET-H2416-16 Titanium Retainers

Supertech KPR-5.5-7A-ST-32 Valve Keepers

Brain Crower (PAC Racing) BC0089S Valve Springs and Steel Retainers

Crower Cams and Equipment Co. 86115-16 Valve Keepers

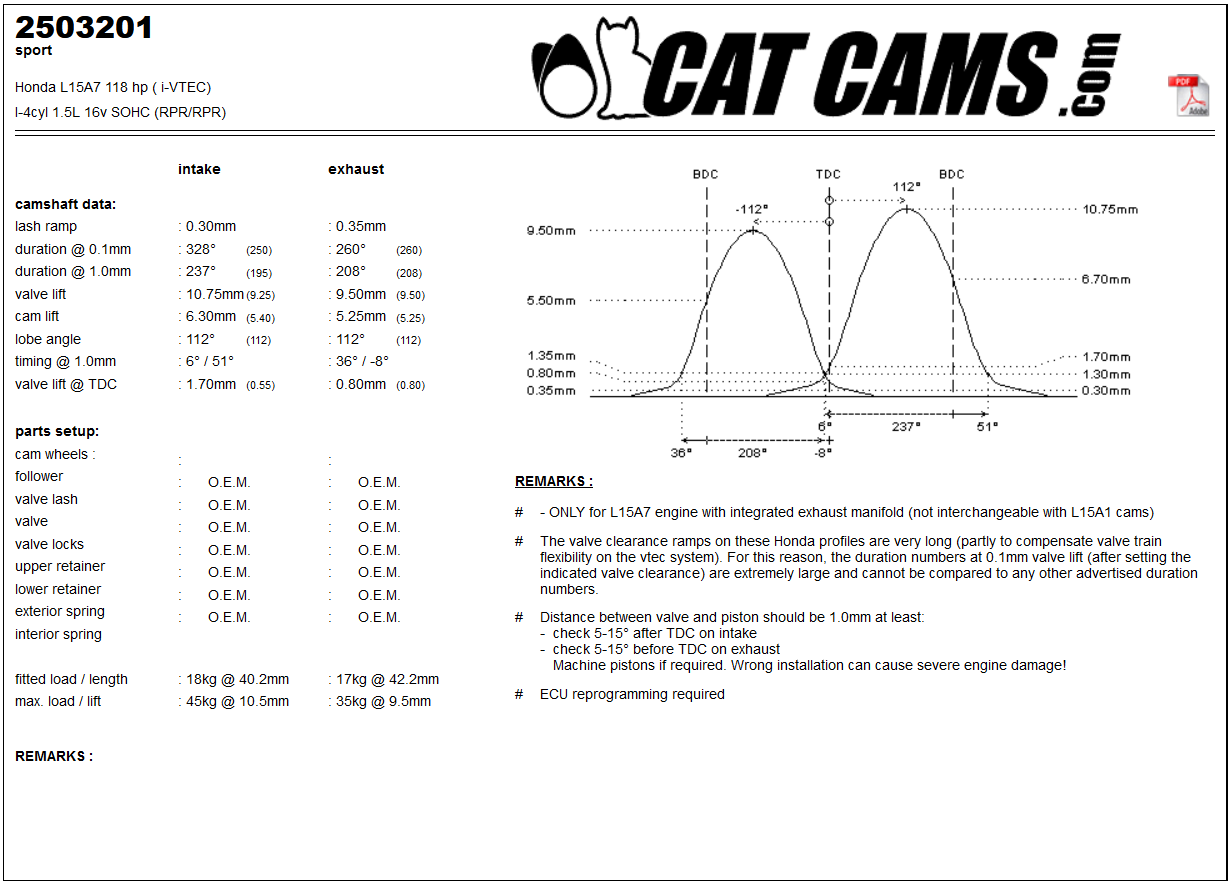

CAT CAMS 2503201 Sport Camshaft

eBay Titanium Tappet Nut: Flange machined to match diameter of Rocker Arm

eBay Titanium Tappet Nut: Standard, no flange

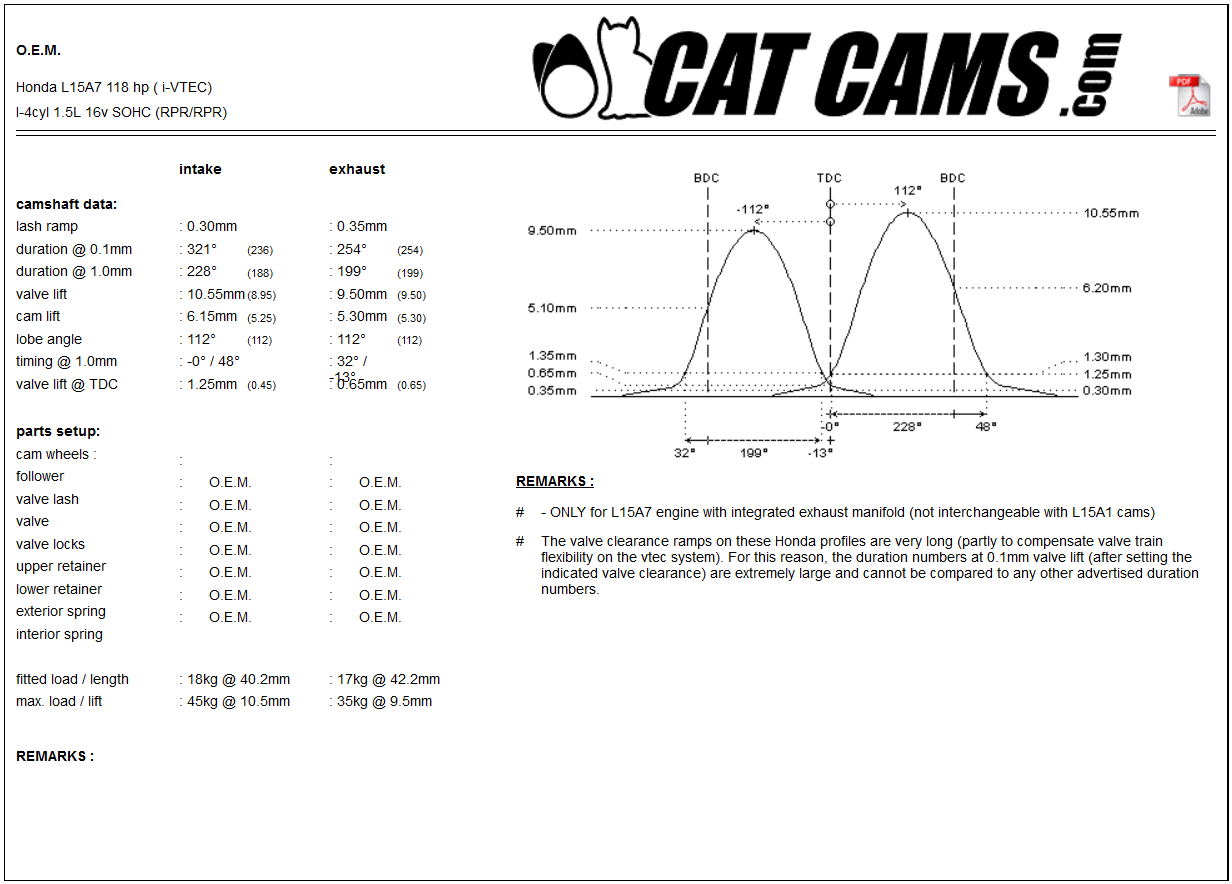

Camshaft Profiles

Below are the two Camshaft profiles considered in this study. Both spec sheets are available from CAT Cams’ website:

The intake lift of the CAT Cams Sport Cam increases by 1.9% over OEM while the duration at 1.0mm increases by 3.9% on the intake side and 4.5% on the exhaust side. This increase in duration relative to lift actually slows the average acceleration of the valve and reduces peak load on the camshaft.

Valvetrain Mass

In preparation for the coming calculations, I measured the mass of each valvetrain component on the L15A7 setup. Keep in mind these components are the same as the LEA1 with the exception of the rocker arms. To help average out any manufacturing variations, I weighed sets of components divided that mass by the count of components to arrive at the following numbers:

| OEM Components | Mass (g) |

| Intake Valve | 35.78 |

| Exhaust Valve | 30.59 |

| Valve Retainer | 6.47 |

| Machined Titanium Supertech Retainer | 5.49 |

| OEM Valve Keeper (pair) | 0.93 |

| Intake Spring | 30.62 |

| Exhaust Spring | 31.82 |

| Supertech Components | Mass (g) |

| Black Nitride Intake Valve | 35.97 |

| Inconel Exhaust Valve | 31.08 |

| Titanium Valve Retainer | 6.00 |

| Supertech Valve Keeper (pair) | 0.97 |

| Intake/Exhaust Valve Spring | 34.70 |

| Brian Crower (PAC Racing) Components | Mass (g) |

| Steel Valve Retainer | 8.54 |

| Intake/Exhaust Valve Spring | 31.74 |

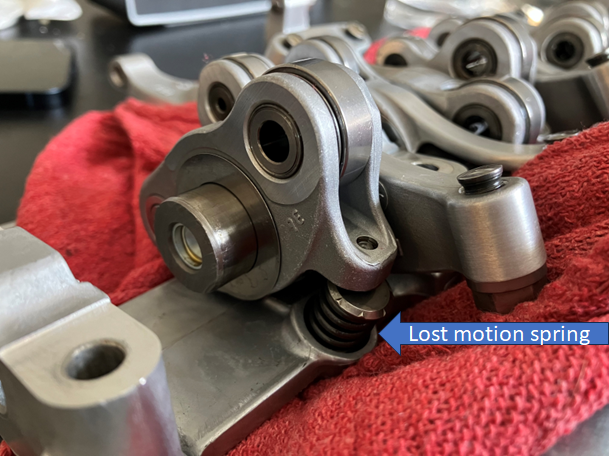

| Cam Side Components | Mass (g) |

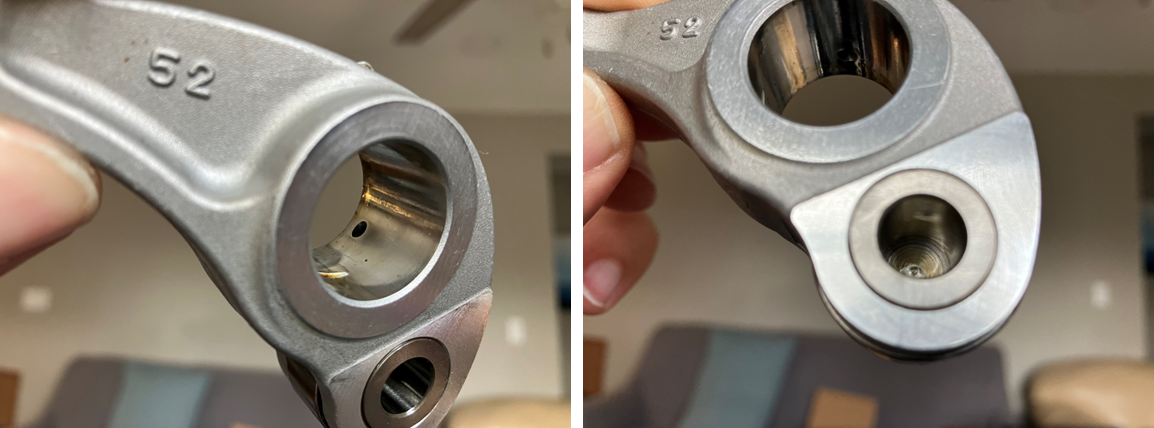

| Exhaust Rocker Arm | 72.13 |

| Primary Intake Rocker Arm | 150.66 |

| Secondary Intake Rocker Arm | 101.50 |

| Tappet | 6.47 |

| OEM Tappet Jam Nut | 2.63 |

| Machined Flange Titanium Tappet Jam Nut | 2.38 |

| Titanium Tappet Jam Nut | 1.62 |

Measurement Confidence

Measurement Confidence

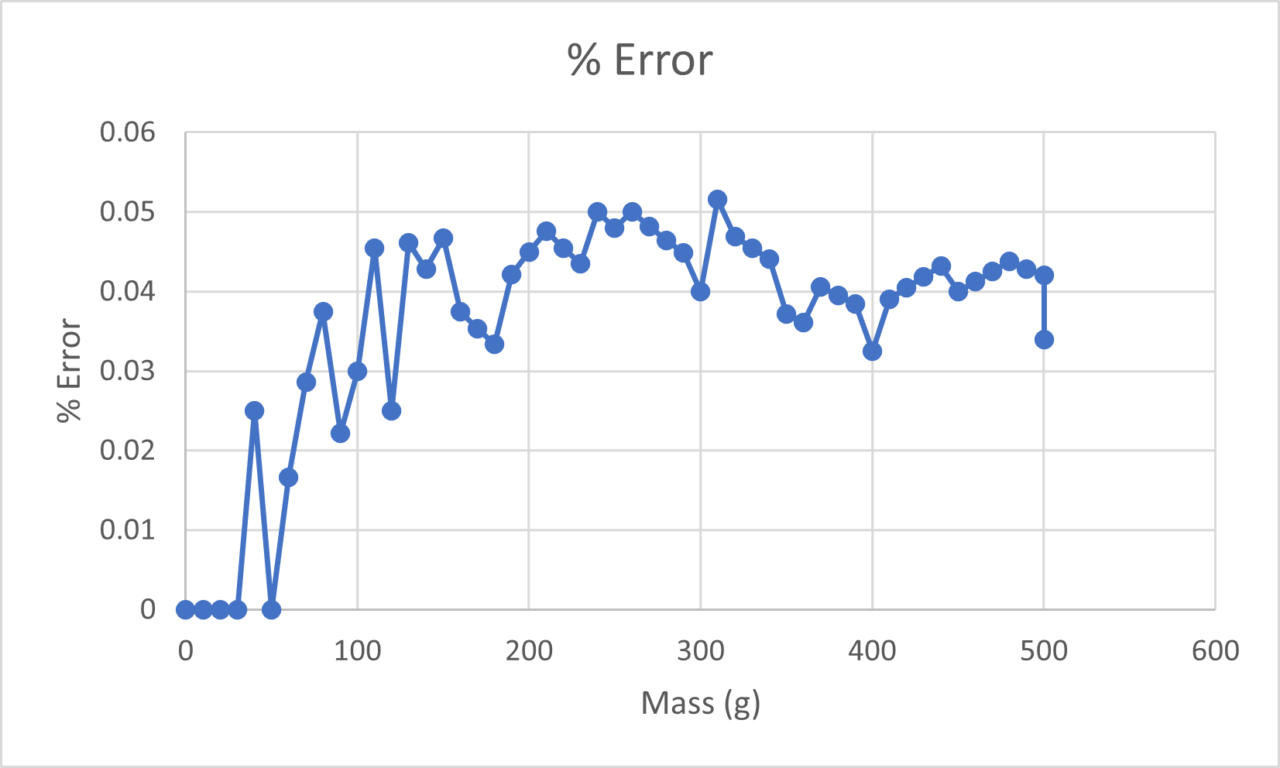

The scale used to measure all of the valvetrain parts was tested with a set of calibration weights in 10g (2%) increments up to its maximum capacity of 500g. Assuming maximum error with the heaviest component, the primary intake rocker arm, the scale would read 0.08g higher than actual.

Leave a Reply